Bioproducts Engineering

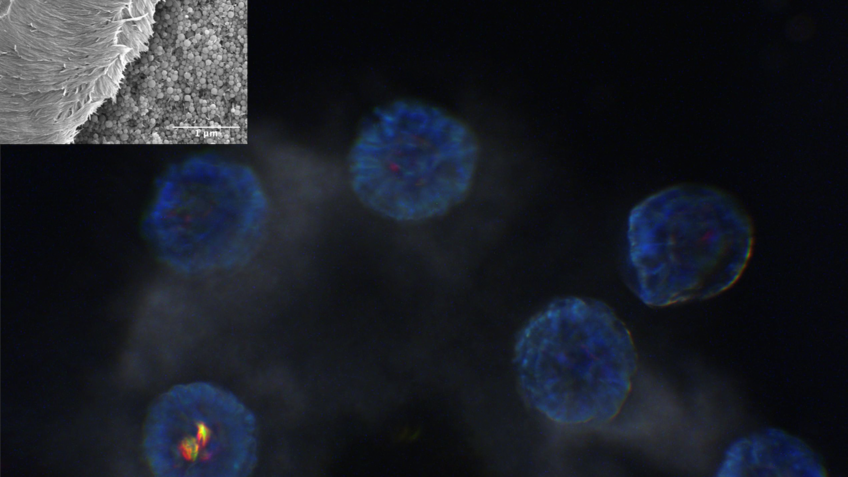

Cellulose NanoCrystals (CNCs) are rod-shaped nanoparticles of crystalline cellulose, which can be directly isolated from plant materials, usually by acid hydrolysis of purified cellulose. Depending on the acids used for the hydrolysis, the CNCs’ surface is grafted with charges, allowing their effective dispersion in water. Interestingly, CNCs suspensions behave as lyotropic liquid crystals, known to self-organize into a cholesteric liquid crystal phase beyond a critical mass fraction. After the removal of water, the cholesteric structure can be maintained, and this periodicity is reduced to sub-micrometer values, giving rise to a Bragg-like reflection of visible light. The resulting dry film becomes intensely colored, resembling the intense and vivid coloration observed in nature.

Whereas using CNCs as an alternative to inorganic pigments is promising, the traditional production route of CNCs for photonic applications requires large volumes of strong acids, alkaline, and water consumption, with severe environmental impact. Additionally, we must consider the challenge of processing different feedstocks, especially the presence of other major components such as hemicelluloses, lignin, fatty acids, etc., on the self-organization into a cholesteric liquid crystal phase and later photonic film.

Our group aims to develop sustainable green processes to isolate CNCs from lignocellulosic biomasses and the recovery of side products using a circular economy approach and via bottom-up/top-down strategies. We work towards a deep understanding of the principles of self-assembly by using model compounds, and we translate this knowledge into a process design for biomass valorization.