Metal Nitride and Metal Carbide

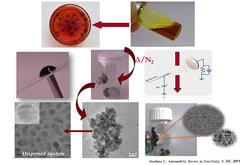

Using urea to play the double role of nitrogen/carbon source and stabilizing agent, several metal carbides and nitrides have been synthesised (Figure 1) with sizes ranging between 5 and 30 nm in diameter and high specific surface area (up to 400 m2/g). Synthesised MN and MC are almost pure and highly crystalline. Special advantage of this procedure is a glassy metal-urea starting material which makes procedure versatile, allowing e.g. to switch in some cases from MN to MC simply by adjusting the urea/metal precursor molar ratio (R) or the direct access to more complex structures such as Fibres (Figure 2).

Novel Routes to Nano MN/MC

Synthetic pathway

Figure 1. Schematic representation of the experimental procedure.

Methodology

Figure 2. Cr-urea derived sample before and after heating treatment and corresponding TEM image. It is interesting to see that CrN nanoparticles are covered by an extremely defined (ca. 2-4 nm thick) carbon coating (CrN@C).

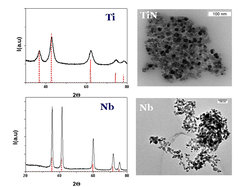

XRD patterns (left side) and corresponding TEM micrograph (right side) of TiN (up) and NbN (down) nanoparticles. Reference patterns are reported in red.

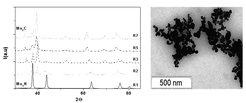

XRD patterns of Mo-urea derived samples at different urea/metal precursor molar ratio; increasing the ratio pure Mo2N or Mo2C can be obtained respectively. On the right side, TEM image of Mo2N (R=1).