Stretching the Limits:

A New Method Maps Elasticity in 3D and Real-Time

Materials can temporarily change shape when a force is applied, a process known as elastic deformation. To measure this, scientists analyze a slight color change in the light that a material reflects under a laser beam. Dr. Shahrouz Amini and his team have extended this method to capture elasticity in real time and in 3D. They use an inverted nanoindenter – like a tiny pencil tip, but made of diamond – to apply stress to a sample material and a laser beam to map the resulting deformation. The accurate study of elasticity enables the design of tailor-made materials for applications ranging from microelectronics to prosthetic implants.

Elastic deformation is all around and within us: the rubber bands we snap, the footballs we kick into the goal, and our muscles and skin that stretch as we move are all examples of temporary deformation in response to an external force. They all return to their original shape once the force is removed. Even unexpected materials like our bones slightly bend and compress through elastic deformation. We have all experienced how elasticity can reach its limits: rubber bands and footballs break or, more painfully, muscles and skin can tear just as bones can fracture.

Dr. Shahrouz Amini and his team set out to measure elastic deformations as accurately as possible across various materials, both artificial and natural. In the existing method – called confocal Raman microscopy – laser beams hit a target material before and after it experiences a stress force. In the process, atoms in the material slightly change their bindings and vibrate differently, affecting the final wavelength of the light they scatter. Scientists then compare the wavelength shifts between the initial and final scattered light to describe the material's mechanical behavior.

This method provides an overview and captures what happens at the surface after a material has been elastically deformed. But Amini and his colleagues wanted to zoom in on the process as it unfolded. "We wanted to measure in real time and with high resolution. We wanted to watch a movie, so to speak, instead of flipping through before-and-after snapshots," Amini says enthusiastically. To achieve this, "we had to change our perspective and think upside down, quite literally," adds Prof. Peter Fratzl.

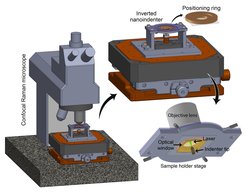

So far, scientists have placed their material under a nanoindenter – a kind of sharp pencil tip thousands of times smaller than a human hair that presses down to apply stress. Amini and his team did the opposite and inverted the setup: they mounted their sample on a platform that sits above the nanoindenter. This way, laser beams hit the sample from the top, and the indenter below does not interfere with the wavelengths the scientists are registering. The result is a 3D map that reveals how materials deform differently at different depths and locations.

Amini and his colleagues stretched their minds to find a way to accurately measure elasticity in action. Now, others can use the 3D-RISM (3D Raman Indentation Strain Mapping) to take inspiration from natural materials like teeth, seashells, and minerals and design materials with tailored properties, from building materials to improved prosthetic implants.