Materials Out of Thin Air?

How Bubbles Make Silica Aerogels

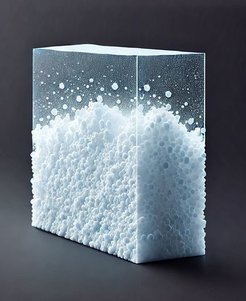

Silica aerogels are among the lightest solid materials and effective insulators thanks to their unique network of pores - much like a sponge filled with air instead of liquid. X-ray examinations found that bubbles are critical to maintaining the pores during aerogel formation. The emergence of bubbles (called "cavitation") prevents the material from collapsing and points to low-cost alternative manufacturing methods with varied applications in the construction industry.

Imagine a super-light sponge with pores filled with air instead of liquid. That’s close to what silica aerogels are. These materials have been around since 1931, when a chemical engineer successfully dried out the liquid component in gels and replaced it with air without shrinking the inner network of pores. This unique porous structure gives silica aerogels their distinctive properties: they are among the lightest solid materials and highly efficient thermal insulators.

But how do these materials keep their shape out of what is essentially thin air?

Julien Gonthier devoted his PhD to better understanding the complex process that makes silica aerogels possible. The initial solid ingredients (the 'precursors') are not hard to come by—silicon is found in sand—and are then 'cooked' in a liquid (a 'solvent') to form a gel. "The tricky and fascinating part comes when you dry the liquid to obtain the aerogel. The process has to be closely controlled to preserve the pores so that air can penetrate," Gonthier explains. Various techniques exist; most require expensive equipment to get the empty spaces right.

With the supervision of Dr. Wolfgang Wagermaier, Gonthier exposed the sample material to X-rays and monitored the drying process over time. Its different components —solid, liquid, and gaseous— transmit X-rays differently at different stages. “These snapshots provided the material’s unique signature: we analyzed them to locate the components and measure their density”- Dr. Ernesto Scoppola describes the images that the team collected and used to create a 3D model of how the liquid gradually evaporates.

Bubbles, it turns out, are crucial to maintaining the coveted pore structure. They form in the liquid part in a process that scientists call ‘cavitation’ and that we can observe every time we boil water. In our pots, it is the sudden change in temperature that creates bubbles. In an aerogel, bubbles form when the liquid solvent evaporates through the porous structure, causing an abrupt change in pressure. These bubbles are short-lived but act like cushions that relieve pressure and prevent the gel from cracking and collapsing. The bubbles eventually dissolve, leaving room for air to fill the pores and for scientists to envision new possibilities. Slow drying at normal atmospheric pressure and temperature could be a valuable alternative for making silica aerogels more simply and cost-effectively.